Removing the LD from the Aixiz module

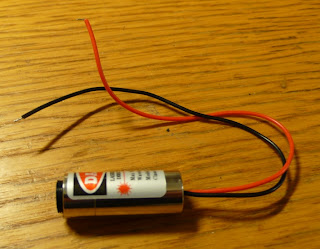

OK, I finally got on with this project. Next step for me was to remove the existing laser diode (LD) from the 650nm Aixiz module. Here's the 650nm 5mW Aixiz module before the operation. The original plastic lens and spring has been removed. The upper lens in the picture is the glass lens, which I'll use later for the burning laser. The module can be screwed open, but it is REALLY tight. They've used some white glue and I needed to use pliers to get it open. Using pliers leaves some little marks on the metal, but it doesn't matter. Using pliers to get the Aixiz module open. Next I needed to remove the original laser diode & driver electronics from the module. I used a nail and a hammer to kick the LD out. It will break but I don't need it. If you want to save the LD & the electronics, here's a good way to get it out without breaking it. The original laser diode and the small driver PCB are visible. Here's the module after removing t